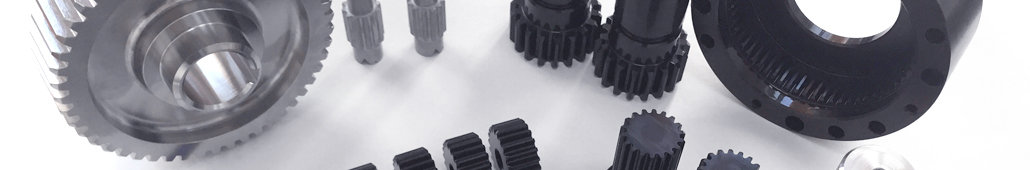

ELECTROPLATED COATING

Electroplating provides reliable protection of products from the corrosion, significantly prolongs its life cycle in hostile environment, improves the habitus and gives a variety of additional features.

Galvanics – covering of details with micro-thin layer of a certain alloy.

Selection of the overcoat is carried out taking into account the usage environment, designation and material of covered product.

Operation of electroplated coating is performed by dipping of the finished part in the plating tank where under the flow of electricity it’s covered by lightweight film of chosen metal. Depending on the material of the product and alloy used for coating, electroplated coating of the metal will be anodic or cathodic.

Equipment of galvanic sector of Alpha Centre allows to make:

- Zinc coating for increasing protection of various types of corrosion and mechanical damage.

- Chromizing to strengthen hardness, steadiness to mechanical wear, for brightening.

- Nickel coating for protection from the corrosion and increasing life cycle of the product.

- Cadmium coating – alternative galvanizing for protection against corrosion and to increase resistance to mechanical damage.

- Copper coating, treatment to improve the durability to friction, prevention of spark formation and for decorative purposes.

- Chemical oxidation.

- Coslettizing.

Specialization – small-lot production and products that require custom-tailored approach.

Main features of materials processed by electroplated coating sector of Alpha Centre:

- width up to 600 mm

- height up to 600 mm

- length up to 600 mm

- covered materials: ferrous metals, aluminium.